| 1. Base Film Resins We blend raw material, a sort of polyolefine like EVA, LDPE, LLDPE, for each product Required film softness, elongation, etc  - Base film Resins - |

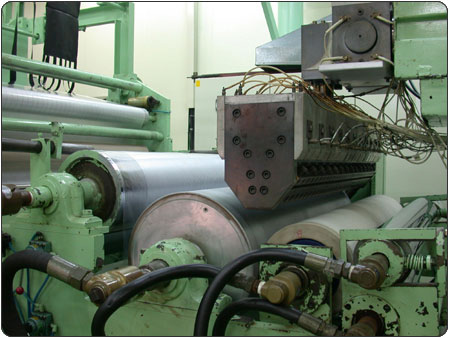

| 2. Base Film Production T-die extrusion facility, designed with high technology and accuracy, can control the base film from 50㎛m to 250 ㎛ under ±5% thickness uniformity. We can manufacture the high quality base film, which can be applied to mega DRAM processing, by ourselves.  - Base film Extruder - |

| 3. Adhesive Raw Materials In the adhesive for semiconductor processing, there are many materials such as Acrylic Adhesive, Acry1. Emulsion Adhesive, UV oligomer, UV monitor, UV initiator and other additives. They are also manufactured and under the rigid quality control management.  - Adhesive Raw Materials - |

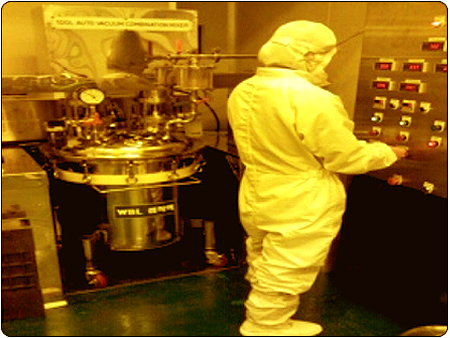

| 4. Adhesive Blending The adhesive manufactured under rigid Q.C. system are blending at each blending recipe with our advanced technology.  - Blending Facility - |

| 5. Adhesive Coating/Drying/Combine The adhesive coating equipment coat the adhesive on the base film and dry it. In doing so, especially, the coated film is dried by the hot air filtered by HEPA filter.  - Adhesive Coating - |

| 6. Inspection The dried film at particle, fish-eye and adhesive thickness is inspected by our skillful engineer in the range of our quality control specification.  - Inspection - |

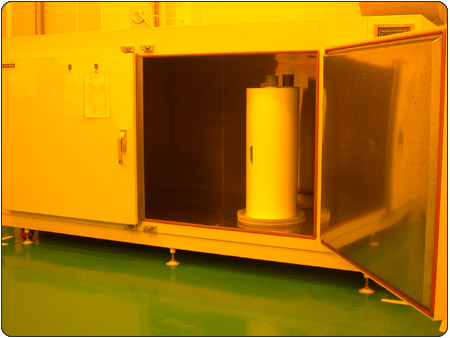

| 7. Aging After coated, dried and inspected, the coated film is aged in the clean oven to make better the adhesive between adhesive and base film and stabilize the adhesive strength through the stabilization of the adhesive material.  - Aging Facility - |

| 8. Slitting The product is slit by the requested width for the wafer size.  - Slitting - |

| 9. Measuring After aged under the regulated temperature and time, the product is measured for the property of the adhesive material such as base film, adhesive thickness, adhesive strength and ball tack.  - Measuring - |

| 10. Packaging The label written the lot number, serial number, product name, manufactured date and expire date is attached on the core of film and bag. After done, the tape is packaged  - Packaging - |